Testing a relay is an essential skill for anyone working with electrical components, whether you're a professional technician or a DIY enthusiast. Relays play a critical role in controlling electrical circuits by acting as a switch that opens or closes in response to an electrical signal. When they fail, your entire system can malfunction, leading to significant disruptions or safety concerns. That's why understanding how to test a relay properly is crucial for maintaining the reliability of your equipment.

Relays are found in various devices, from automotive systems to home appliances, and testing them can help diagnose issues quickly and effectively. If you've ever wondered why a piece of equipment isn't working as it should, a faulty relay could be the culprit. By learning how to test a relay, you can save time and money by identifying and resolving the problem yourself without needing professional intervention.

In this guide, we'll dive deep into the step-by-step process of testing a relay, from understanding its components to using tools like multimeters. We'll also explore different types of relays, common issues, and troubleshooting techniques. By the end of this article, you'll have the knowledge and confidence to address relay issues effectively, ensuring your electrical systems operate smoothly and safely.

Read also:John Fiedler A Timeless Voice In Entertainment

Table of Contents

- What is a Relay?

- How Does a Relay Work?

- Why is it Important to Test a Relay?

- Tools Needed to Test a Relay

- How to Test a Relay: Step-by-Step Guide

- What Are the Common Types of Relays?

- What Are the Signs of a Faulty Relay?

- How to Identify Relay Pin Configurations?

- Can a Relay Be Repaired or Should It Be Replaced?

- How to Maintain Relays for Longer Lifespan?

- What to Do If Your Relay Passes Tests But Still Doesn’t Work?

- Frequently Asked Questions About Relay Testing

- Conclusion

What is a Relay?

A relay is an electrical device that uses an electromagnet to control the opening and closing of a circuit. Essentially, it acts as a switch, allowing a low-power signal to control a high-power circuit. Relays are vital components in various applications, including automotive systems, industrial machinery, home appliances, and communication devices.

Relays can be classified into several types, including electromagnetic, solid-state, and thermal relays, each designed for specific purposes. Their primary role is to enable a circuit to control another circuit, which may differ in voltage or current levels. This makes them an indispensable part of modern electrical systems.

How Does a Relay Work?

Relays operate on the principle of electromagnetism. When an electrical current flows through the coil of the relay, it generates a magnetic field. This magnetic field activates a switch, either opening or closing the circuit it controls. Depending on the relay’s design, it may have normally open (NO) or normally closed (NC) contacts, which determine its default state when no current is applied.

The ability of relays to isolate and control circuits makes them highly versatile. For example, in automotive applications, a small current from a car’s ignition switch can activate a relay that powers the starter motor, which requires a much higher current. This ensures safety and efficiency in electrical systems.

Why is it Important to Test a Relay?

Testing a relay is essential to ensure that it functions correctly and doesn’t compromise the performance of the system it’s a part of. A faulty relay can lead to severe issues, such as equipment malfunctions, electrical failures, or even safety hazards. Regular testing can help prevent unexpected breakdowns and extend the lifespan of your equipment.

By testing a relay, you can identify whether the issue lies in the relay itself or other components in the circuit. This diagnostic process is crucial for troubleshooting and repair, especially in complex systems where multiple components interact. Testing also ensures compliance with safety and performance standards, particularly in industrial and automotive applications.

Read also:Jlo Drama The Intriguing World Of Jennifer Lopezs Life

Tools Needed to Test a Relay

To test a relay effectively, you’ll need the following tools:

- Multimeter: A versatile tool for measuring voltage, current, and resistance.

- Test Light: Useful for checking continuity and power flow in circuits.

- Power Source: A 12V battery or power supply to activate the relay.

- Jumper Wires: For connecting the relay to the power source and multimeter.

- Relay Wiring Diagram: Helps identify the pin configuration and connections.

Having these tools on hand will make the testing process straightforward and efficient. Ensure that your tools are in good condition and suitable for the type of relay you’re testing.

How to Test a Relay: Step-by-Step Guide

Testing a relay involves several steps, depending on whether you’re testing it in isolation or within a circuit. Follow these guidelines for accurate results:

Testing a Relay with a Multimeter

Using a multimeter is one of the most reliable methods for testing a relay. Here’s how to do it:

- Identify the relay’s pin configuration using its wiring diagram.

- Set your multimeter to the resistance (ohms) setting.

- Check the resistance between the coil terminals. A functional relay will have a specific resistance value, usually indicated in the datasheet.

- Connect a power source to the coil terminals to activate the relay.

- Measure the resistance between the switch terminals. The resistance should change from infinite (open) to near zero (closed) when the relay is activated.

Testing a Relay in a Circuit

If the relay is already installed in a circuit, follow these steps:

- Use a test light or multimeter to check for voltage at the relay’s input terminals.

- Activate the circuit to trigger the relay.

- Verify that the output terminals have the correct voltage or continuity.

This method helps confirm whether the relay is functioning as intended within its operational environment.

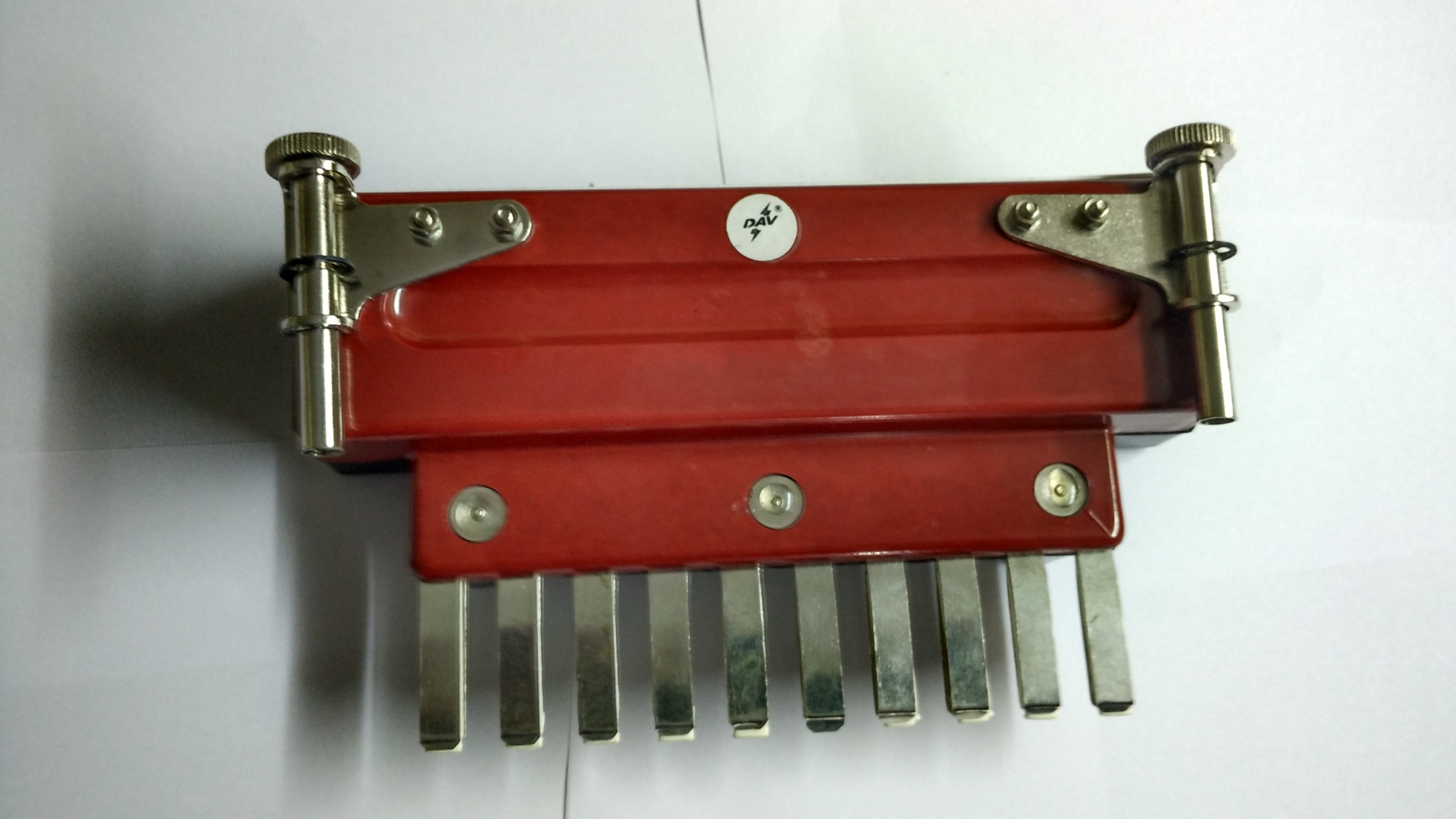

What Are the Common Types of Relays?

Relays come in various types, each suited for specific applications:

- Electromagnetic Relays: Use an electromagnet to open or close contacts.

- Solid-State Relays: Employ semiconductor components for switching, offering faster and quieter operation.

- Thermal Relays: Use heat-sensitive components for overload protection.

- Reed Relays: Feature contacts sealed in a glass tube, activated by a magnetic field.

Understanding the type of relay you’re working with is crucial for accurate testing and troubleshooting.

What Are the Signs of a Faulty Relay?

Common symptoms of a faulty relay include:

- Intermittent operation or failure to activate.

- Unusual noises, such as clicking or buzzing.

- Burnt or damaged contacts.

- Overheating or discoloration.

Recognizing these signs can help you address issues promptly and prevent further damage to your system.

How to Identify Relay Pin Configurations?

Relay pin configurations can vary depending on the type and manufacturer. Most relays have a diagram printed on their casing, indicating the coil and switch terminals. Refer to this diagram and use a multimeter to verify the connections if necessary. Understanding the pin configuration is essential for accurate testing and installation.

Can a Relay Be Repaired or Should It Be Replaced?

While some relays can be repaired, such as by cleaning contacts or replacing damaged components, most are designed to be replaced when they fail. Repairing a relay often requires specialized tools and expertise, making replacement the more practical option for most users.

How to Maintain Relays for Longer Lifespan?

To extend the lifespan of your relays, consider these maintenance tips:

- Keep the relay and its surroundings clean and free from dust.

- Ensure proper ventilation to prevent overheating.

- Use relays within their specified voltage and current ratings.

- Inspect relays regularly for signs of wear or damage.

What to Do If Your Relay Passes Tests But Still Doesn’t Work?

If your relay passes all tests but the system still doesn’t work, consider these possibilities:

- Faulty wiring or connections in the circuit.

- Issues with other components in the system.

- Incorrect relay specifications for the application.

Thoroughly inspect the entire system to identify and address the root cause of the problem.

Frequently Asked Questions About Relay Testing

- Can I test a relay without a multimeter? Yes, you can use a test light or other methods, but a multimeter provides more accurate results.

- How do I know if a relay is bad? Signs include intermittent operation, unusual noises, or failure to activate.

- Can a relay fail intermittently? Yes, relays can exhibit intermittent failures due to worn contacts or coil issues.

- What is the lifespan of a relay? It depends on the type and usage, but most relays last for thousands of cycles.

- Is it safe to test a relay while it’s in a circuit? Yes, but take precautions to avoid short circuits or damage to other components.

- Can I use any relay for my application? No, always choose a relay with specifications that match your system’s requirements.

Conclusion

Learning how to test a relay is a valuable skill that can save you time, money, and frustration. By following the steps outlined in this guide, you can diagnose and resolve relay-related issues effectively, ensuring the smooth operation of your electrical systems. Regular testing and maintenance are key to extending the lifespan of your relays and preventing unexpected failures. With the right tools and knowledge, you can tackle relay problems confidently and keep your equipment running at its best.

For further reading on advanced relay testing techniques, visit Electronics Notes.